NICKEL BASED MASTER ALLOYS

Home Reach Us

Home Reach Us

Insmart Dhatu India Master Alloys has been working constantly and continuously to develop a new line of a master alloys and manufactures highest quality nickel and Aluminum master alloys for both foundry and vacuum melting applications in Vacuum Induction Melting furnaces

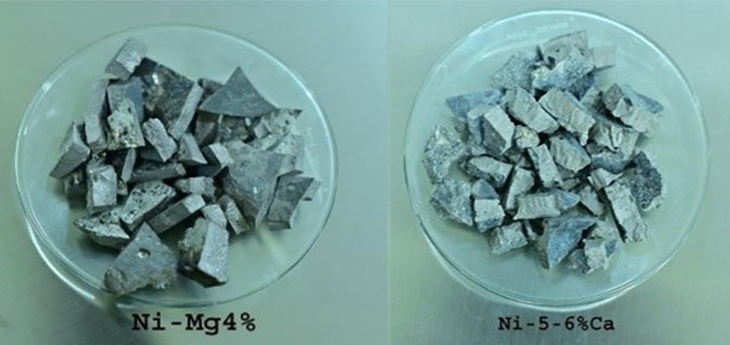

Ni-Mg is utilized for Deoxidation and desulphurization of special steels

and Modularized in SG iron.

Ni-ca is mainly utilized for desulfurization and deoxidation of Ni based alloys,

stainless and heat resistant alloys, and low alloyed steel.

Ni-B is used for Alloying boron into amorphous alloys, Production of wear resistant

Ni steels, Deoxidizer and nitrogen scavenger in super alloys and Enhancing fluidity

of Ni alloys Deoxidizer for CuNi alloys.

Ni-Cr is used for Solid solution strengthening, increasing corrosion resistance of Ni

based brazing alloys.

Ni-Nb is used for improving the mechanical properties of Ni based steels, super

alloys and CuNi alloys.

Ni-Ti is used for Precipitation hardening of nickel based super alloys.

Ni-V is used to incorporate vanadium in steel to improve tensile strength and other

properties; have application in shape memory alloys, magnets and semiconductors.

Ni-Zr is used for Improving creep strength and ductility of nickel based super

alloys.

| MATERIAL SPECIFICATION | COMPOSITION | DENSITY | LUMPS SIZE | |

|---|---|---|---|---|

| Nickel Magnesium | IDI-Ni 5 Mg | Mg-04-08% Ni-Balance | 8.47 | 10-100 mm |

| IDI-Ni 15 Mg | Mg-14-16% Ni-Balance | 7.76 | 10-100 mm | |

| IDI-Ni 17 Mg | Mg-16-18% Ni-Balance | 7.68 | 10-100 mm | |

| Nickel Calcium | IDI-Ni 5 Ca | Ca-05-06% Ni-Balance | 8.45 | 10-50 mm |

| IDI-Ni 9 Ca | Ca-09-10% Ni-Balance | 8.16 | 10-50 mm | |

| Nickel Boron | IDI-Ni 15 B | B-15% Ni-Balance | 7.9 | 10-50 mm |

| Nickel Yttrium | IDI-Ni 10 Y | Y-08-15% Ni-Balance | 8.9 | 10-50 mm |

| Nickel Aluminum | IDI-Ni-A l | Ni-50% Al | 9.0 | 10-50 mm |

| Nickel - Molybdenum | IDI-Ni-Mo | Ni–50% Mo | 8.5 | 10-50 mm |

| Nickel Chromium | IDI-Ni - Cr 20 IDI-NICR 50 |

Ni - 20% Cr Ni - 50% Cr |

7.7 | 10-50 mm |

| Nickel-Niobium | IDI-NiNb 65 | Ni – 65% Nb | 8.6 | 10-50 mm |

| Nickel– Titanium | IDI-Ni - Ti 35 IDI-NiTi 50 |

Ni – 35 % Ti Ni - 50 % Ti |

8.5 | 10-50 mm |

| Nickel - Vanadium | IDI-Ni - V 60 | Ni - 60 % V | 7.1 | 10-50 mm |

| Nickel-zirconium | IDI-Ni - Zr 50 IDI-NiZr 70 |

Ni – 50 % Zr Ni – 70 % Zr |

7.5 | 10-50 mm |